Grimshaw designs range of shipping-container coronavirus testing centres

The New York office of architecture studio Grimshaw has drawn up plans for a range of prefabricated coronavirus testing centres within shipping containers, named D-Tec. Grimshaw designed the prefabricated facilities for healthcare company Osang and engineering company SG Blocks to provide mass testing for the Covid-19 coronavirus. "We were approached by Osang and our long term collaborators, The post Grimshaw designs range of shipping-container coronavirus testing centres appeared first on Dezeen.

The New York office of architecture studio Grimshaw has drawn up plans for a range of prefabricated coronavirus testing centres within shipping containers, named D-Tec.

Grimshaw designed the prefabricated facilities for healthcare company Osang and engineering company SG Blocks to provide mass testing for the Covid-19 coronavirus.

"We were approached by Osang and our long term collaborators, SG Blocks to develop a solution to collect samples but more importantly to be able to process their GeneFinder Covid-19 Plus Real Amp Kit," said Grimshaw chairman Andrew Whalley.

"This is a highly accurate test that can detect Covid-19 at the very earliest a symptomatic stages," he told Dezeen. "The testing process has to be undertaken in a laboratory and the entire process can be completed in under 2.5 hours."

The studio has designed five units that would each be built using shipping containers. The smallest unit, named D-Tec 1, would occupy a single shipping-container, while the largest, D-Tec 5, would be built of five containers.

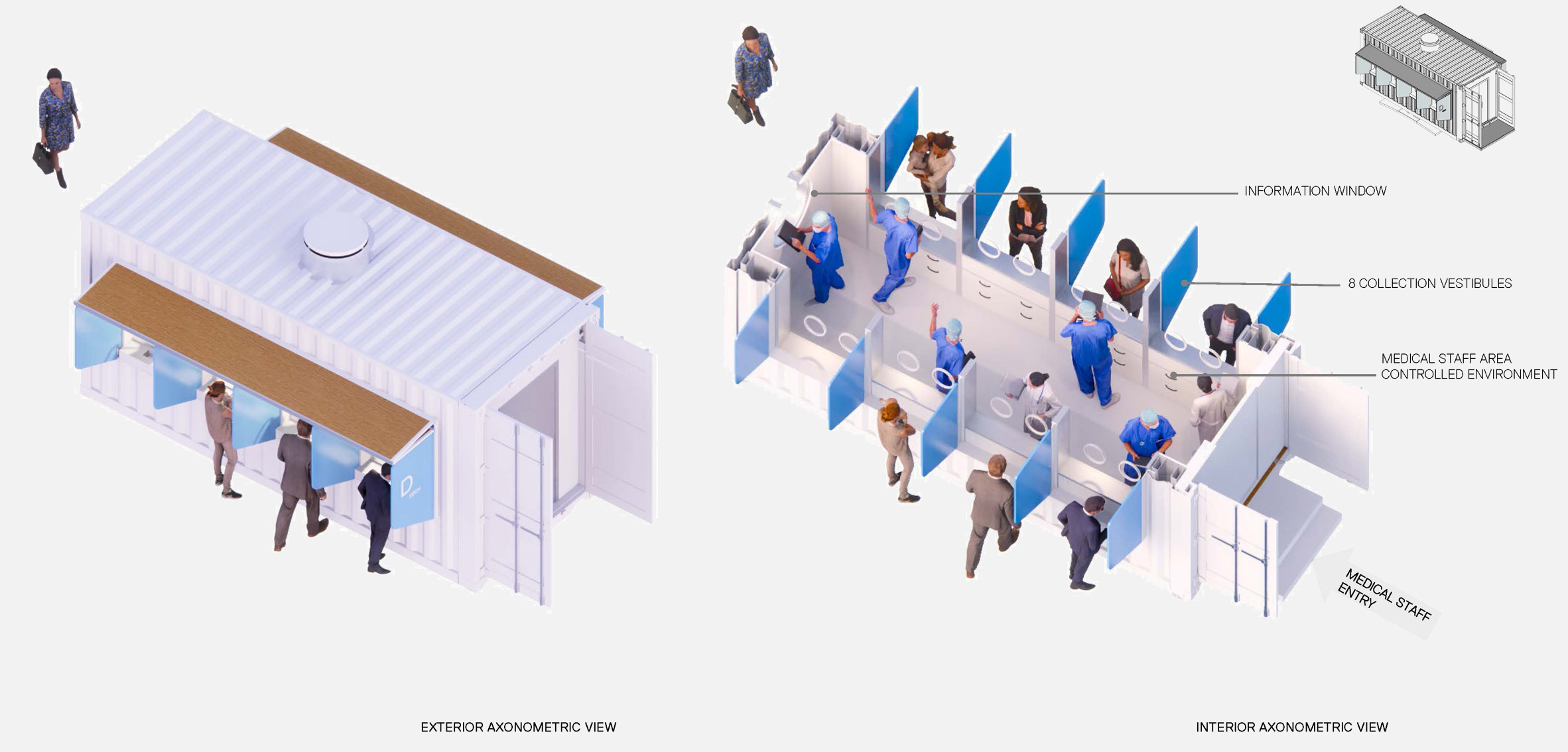

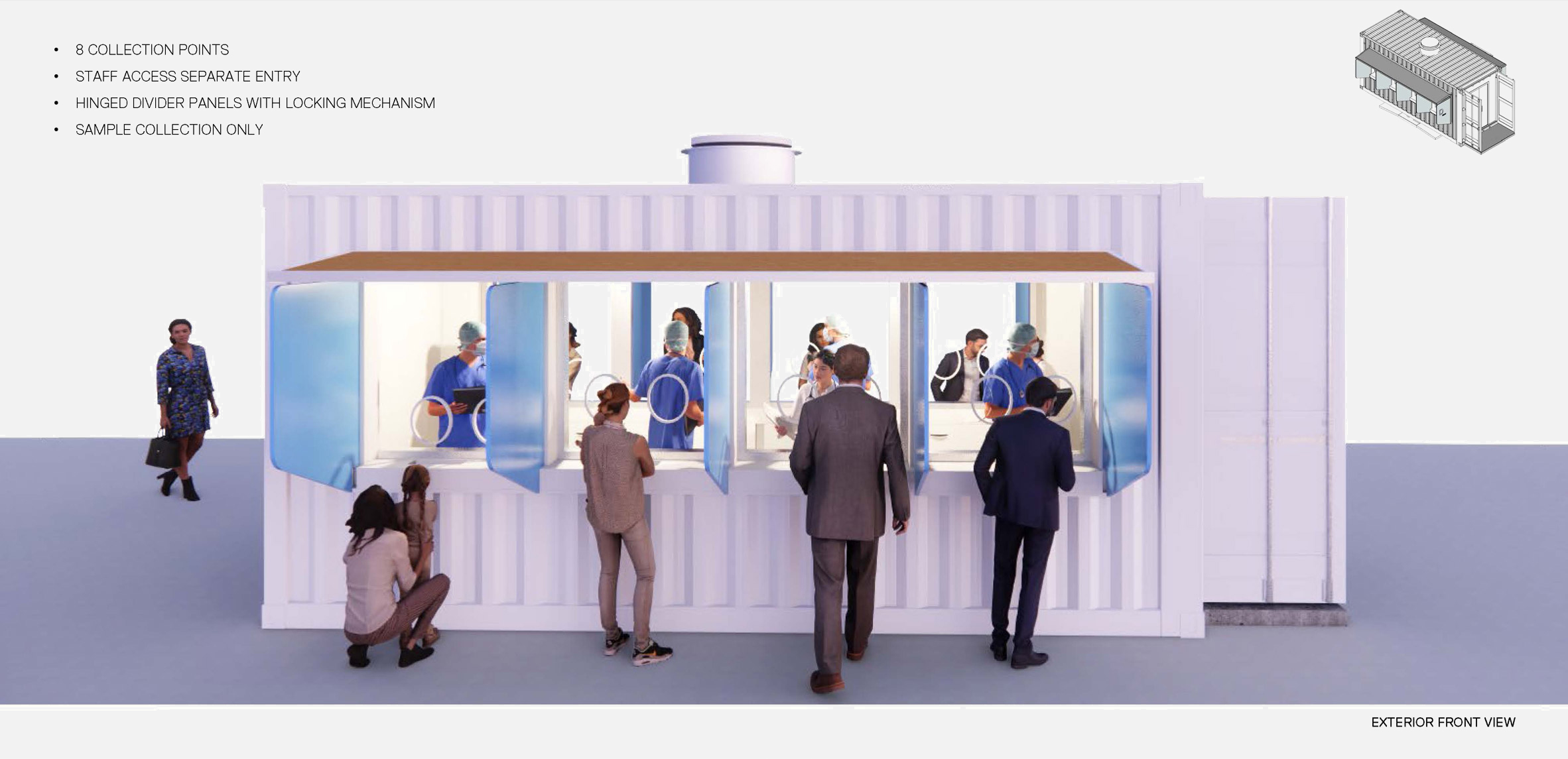

D-Tec 1 is designed to be a sample collection unit and could be configured to have either four or eight collection windows, along with an information window. The collection windows would be sheltered by a moveable section of wall that could be closed for transportation and separated by hinged divider panels.

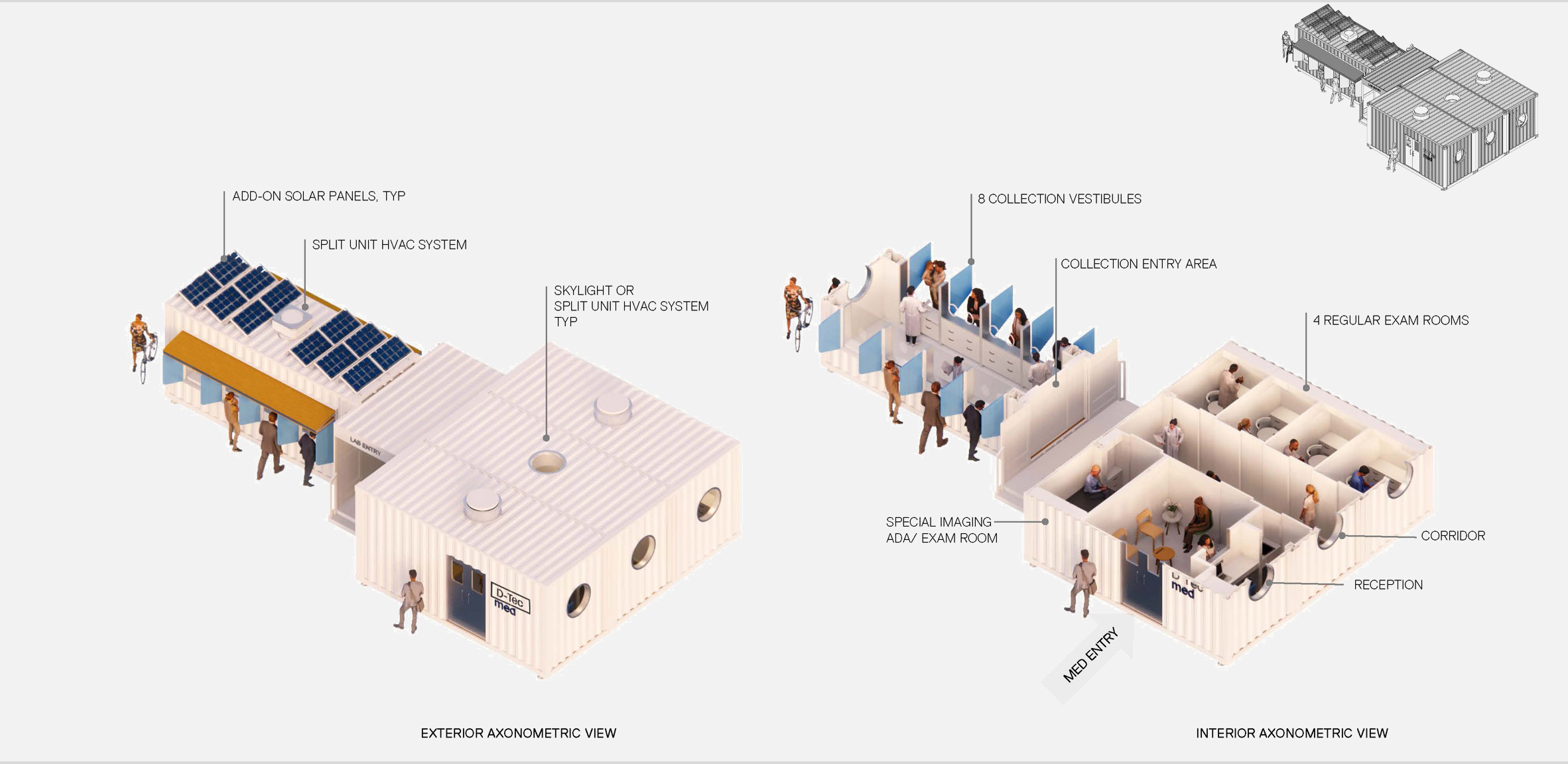

Each of the larger D-Tec 2, D-Tec 3 and D-Tec 4, units combine one of these sample collection units with laboratories for analysing test results or clinics with examination rooms.

The D-Tec 2, has a laboratory and collection units in two containers placed on either side of a central vestibule, while D-Tec 3 and D-Tec 4 incorporate two and three shipping-container clinics, respectively.

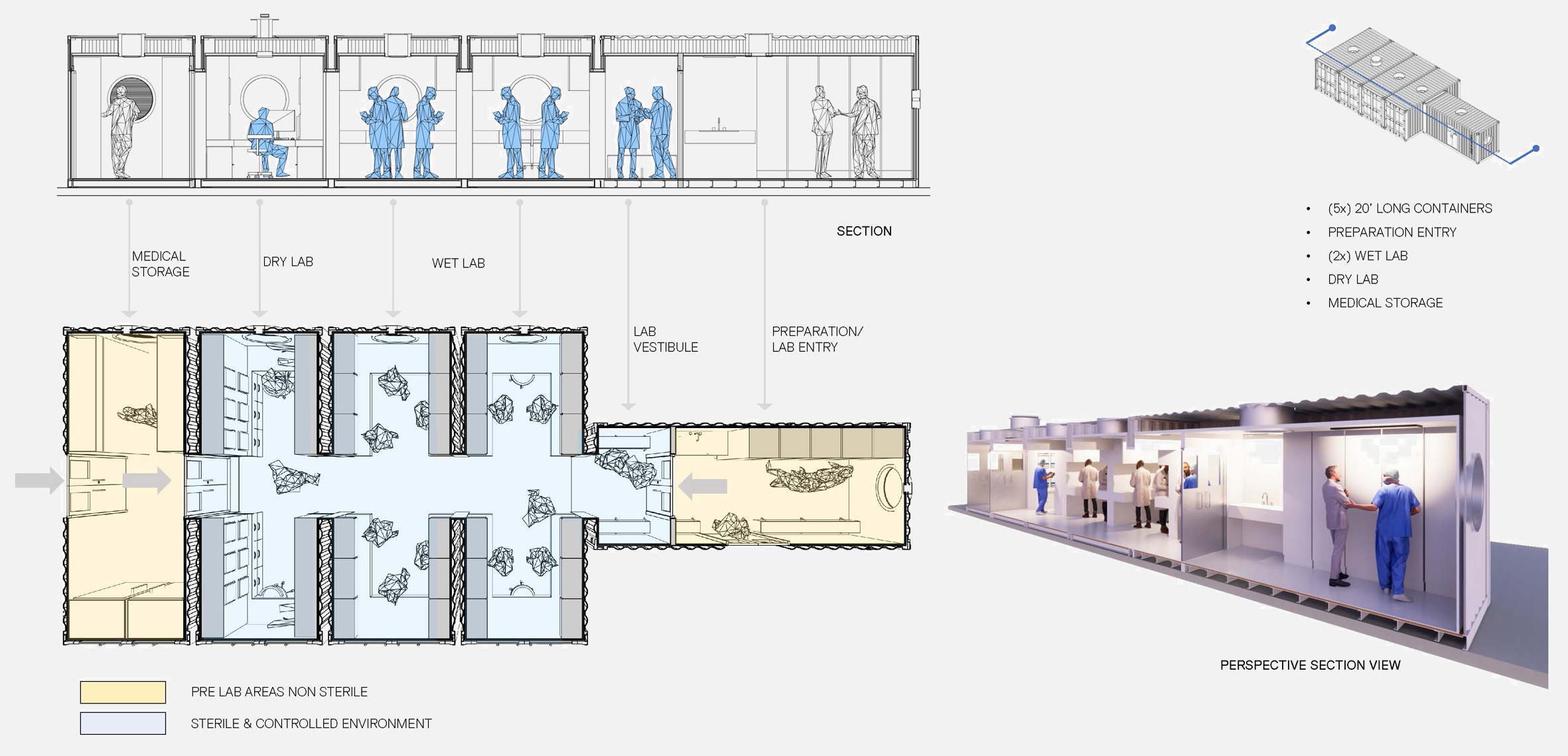

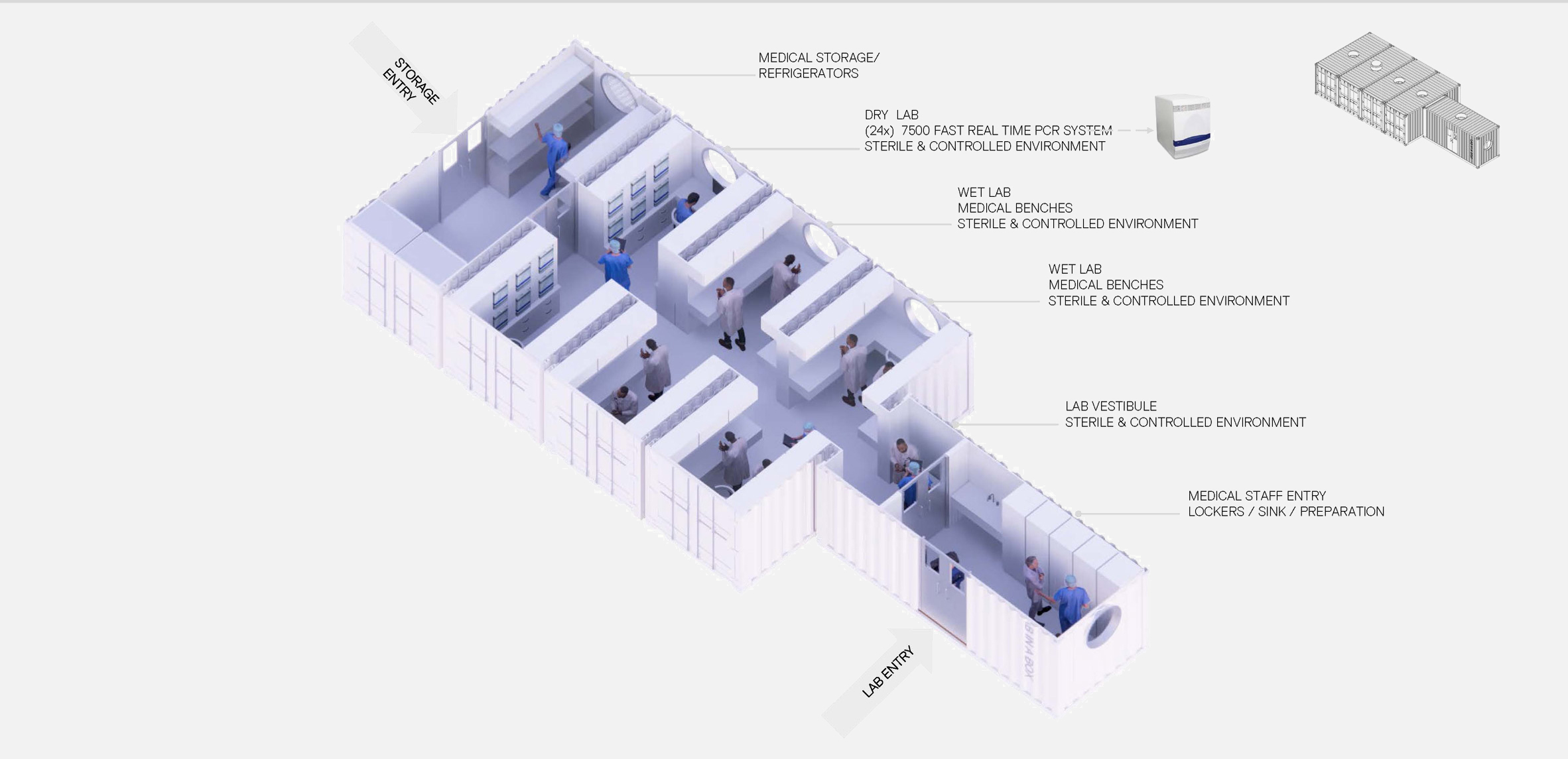

The largest unit, the D-Tec 5, would consists of five shipping containers entirely dedicated to laboratory facilities.

"The D Tec 5 lab cluster can process 750 tests per hour, so over three shifts it will process 18,000," explained Whalley. "We were asked to look at the logistics of organising 20 sets in a number of locations so they could process 350,000 tests over 24 hours."

"The smaller units facilitate testing, processing and health care clinics for remote and rural locations," he continued.

Grimshaw decided to design the range of testing and laboratory units from shipping containers as fabrication could be achieved quickly. Once built, the units could be moved and redeployed where necessary.

"The system needs to be ready to go into operation at scale in six weeks so using readily available shipping containers accelerated the process," said Whalley,

"However it's the logistics that are more important the need to be easy to transport and then to move and redeploy at a new location."

The first prototypes of the D-Tec 1 and D-Tec 2 units are set to be completed in early July, with Grimshaw currently working on a plan to combine these mobile, shipping-container units with permanent facilities.

"We are only considering them [shipping containers] for small scale deployable solutions where the ability to rapidly deploy is essential," explained Whalley.

"We are currently looking at another application where the testing and health check units will be deployed and then replaced over a number of phases with a permanent modular prefabricated system in rural locations," he continued. "The temporary container solution will then move to a new location and the process repeats."

Grimshaw joins Waugh Thistelton and Carlo Ratti in proposing using shipping containers to create structures that help combat coronavirus.

UK architecture studio Waugh Thistleton proposed making 6,500 mobile vaccination centres in shipping containers that could travel around the country, while Italian architects Carlo Ratti and Italo Rota built a prototype intensive-care pod within a shipping container at a hospital in Milan.

Although shipping-container architecture is sometime criticised, Whalley believe that there are both good and bad examples of the modular units being used to build structures.

"I believe they can be if properly designed and there are many good examples, its all about design so equally as with all architecture there are also very poor examples," he said.

The post Grimshaw designs range of shipping-container coronavirus testing centres appeared first on Dezeen.